Unlocking Growth with Reliable fasteners manufacturers in china

In the intricate world of manufacturing and construction, fasteners play a fundamental yet often underappreciated role. These small mechanical components—bolts, screws, nuts, washers, rivets, and more—hold everything together, ensuring structural integrity and durability across countless industries. For global businesses sourcing these vital parts, partnering with reputable fasteners manufacturers in china has become an increasingly strategic choice.

China’s manufacturing sector has grown exponentially over the past few decades, evolving into a powerhouse known for its vast production capacity, competitive pricing, and technical innovation. This article explores why selecting the right fasteners manufacturers in china can provide your business with quality, efficiency, and competitive advantage.

Why China Stands Out in the Fasteners Manufacturing Industry

China is recognized globally as one of the top hubs for fasteners production due to several key factors:

1. Scale and Capacity

With thousands of factories dedicated to fasteners manufacturing, China can serve clients of all sizes—from small batches for prototypes to high-volume mass production runs. This capacity allows flexibility and rapid scalability to meet fluctuating market demands.

2. Cost-Effectiveness

Thanks to economies of scale, advanced supply chains, and relatively lower labor costs, many fasteners manufacturers in china can offer competitive pricing without sacrificing quality. This balance is crucial for companies aiming to reduce production costs while maintaining product reliability.

3. Diverse Product Range

Chinese manufacturers produce an extensive variety of fasteners, including:

- Standard and custom screws

- Hex bolts and flange bolts

- Rivets and pins

- Threaded rods and studs

- Nuts and washers

- Specialty fasteners for automotive, aerospace, electronics, and construction sectors

This product diversity allows buyers to consolidate their sourcing and simplify procurement.

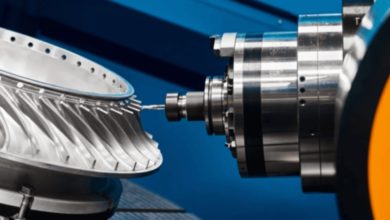

4. Technological Advancements

Leading manufacturers in China invest in modern machinery—CNC cold heading, thread rolling, heat treatment, coating lines, and precision inspection systems—ensuring that fasteners meet stringent global standards such as ISO, DIN, ASTM, and JIS.

See also: How AI Face Swap Technology Is Shaping User-Generated Content

What to Look for When Choosing fasteners manufacturers in china

Selecting the right fasteners manufacturers in china can make a significant difference in your supply chain efficiency and product quality. Here are critical considerations:

✔ Quality Assurance

Ask potential suppliers about their quality management systems. Do they have ISO 9001 certification? What inspection methods do they use? Sampling protocols, tensile testing, hardness tests, and surface finish verification are all essential quality checks.

✔ Material Sourcing

Good manufacturers source raw materials from reputable mills and provide certificates of compliance. Material quality affects corrosion resistance, tensile strength, and overall durability.

✔ Customization Ability

Many businesses require fasteners tailored to their specifications—whether unique sizes, materials, or coatings. A flexible supplier can handle custom orders, provide engineering support, and develop prototypes.

✔ Lead Times and Capacity

Confirm the supplier’s production capacity aligns with your volume needs and delivery schedules. Reliable fasteners manufacturers in china offer transparent lead times and contingency plans for urgent or large-scale orders.

✔ Export Experience

International shipping can be complex. Experienced manufacturers understand export regulations, documentation, and packaging standards, ensuring smooth delivery without costly delays.

✔ Communication and Support

Clear and responsive communication is critical, especially when dealing with overseas suppliers. Choose a manufacturer with English-speaking staff, technical expertise, and a customer-centric approach.

Advantages of Partnering with fasteners manufacturers in china

1. Access to Competitive Prices

Chinese fasteners manufacturers provide cost-effective solutions by leveraging efficient production processes and local supply networks, reducing your total cost of ownership.

2. High Product Quality

China’s top manufacturers are increasingly adhering to international quality certifications and continuous improvement programs, closing the gap with Western producers.

3. Rapid Prototyping and Production

With flexible manufacturing setups, Chinese suppliers can quickly develop prototypes, iterate designs, and ramp up production, speeding up your product development cycles.

4. Broad Industry Expertise

From automotive and aerospace to electronics and construction, many fasteners manufacturers in china have extensive experience supplying to demanding sectors, ensuring compliance with specialized standards.

5. Streamlined Supply Chain

Working with manufacturers who offer a comprehensive product range allows companies to consolidate orders, reduce vendor complexity, and improve supply chain transparency.

How to Establish a Successful Partnership

Building a strong relationship with your fasteners manufacturers in china involves:

- Site visits or virtual factory tours: Understand production capabilities firsthand.

- Clear agreements: Define quality standards, delivery terms, and penalties for non-compliance.

- Regular quality audits: Periodically check compliance through third-party inspections.

- Effective communication: Use technology for real-time updates and problem resolution.

- Long-term collaboration: Engage suppliers in product development and continuous improvement.

Case Study: A Global Automotive Supplier’s Success with Chinese Fasteners

An automotive components manufacturer in Europe sought to reduce costs on their bolt and nut supply without compromising quality. They partnered with a leading fasteners manufacturer in china known for automotive-grade products.

By collaborating on design specifications, testing protocols, and production schedules, the supplier delivered:

- Consistent ISO-certified products

- Reduced lead times by 20% through optimized logistics

- 15% cost savings on components

- Joint development of corrosion-resistant coatings suited for European climates

This partnership became a model for supply chain optimization leveraging China’s manufacturing strengths.

Future Trends for fasteners manufacturers in china

🌱 Sustainability Initiatives

Increasing global demand for eco-friendly manufacturing is driving Chinese suppliers to adopt greener processes, reduce waste, and use recyclable materials.

🤖 Automation and Industry 4.0

Smart factories with AI-driven quality control, robotic assembly, and predictive maintenance are enhancing efficiency and product consistency.

🌐 Digital Procurement Platforms

Integration with e-commerce and procurement platforms improves transparency, order tracking, and supplier evaluation.

Conclusion

For companies seeking reliable, high-quality, and cost-effective fasteners, partnering with experienced fasteners manufacturers in china offers immense strategic benefits. The combination of scale, innovation, and diverse product offerings enables businesses worldwide to meet their production goals efficiently.

Careful supplier selection, proactive communication, and ongoing collaboration are key to unlocking the full value of this partnership. As China’s manufacturing sector continues to modernize and align with global standards, it stands as a powerful ally for fasteners sourcing.

By investing time and resources into finding the right fasteners manufacturers in china, your company can secure a steady, high-quality supply that supports innovation, growth, and competitive advantage.